Industrial Infrastructure Monitoring

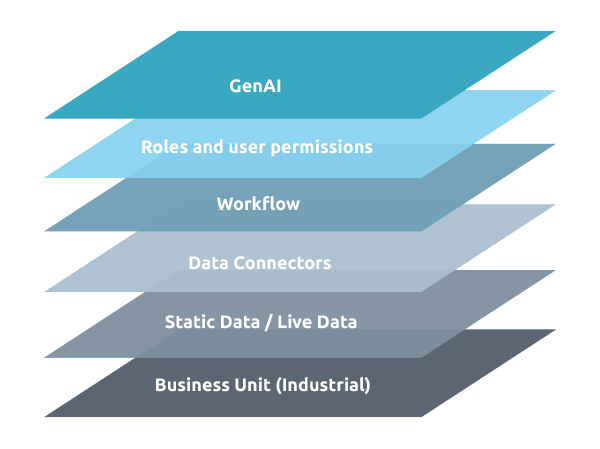

MicroAI’s advanced GenAI (Generative AI) technology, in combination with AT&T’s 5G and IoT capabilities, are transforming industrial infrastructures by providing real-time insights, intelligent decision-making, and automated workflows. Our solutions enhance observability, optimize asset productivity, and improve cyber-security across both IT and OT environments.

Schedule a Demo

Solution for AI-Enabled Industrial Infrastructure

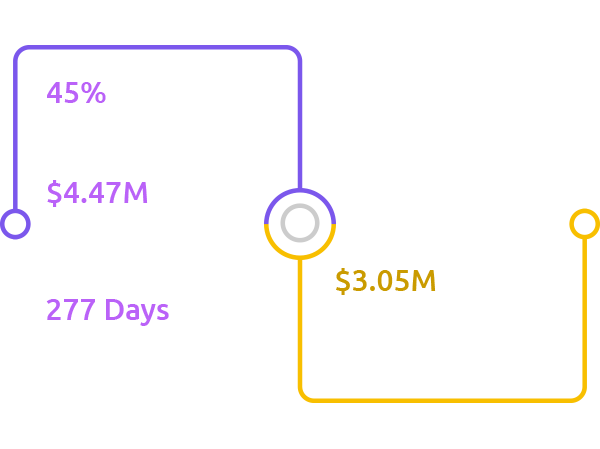

Predictive Maintenance

Eliminate unplanned downtime and extend asset lifespans with GenAI-Enabled Predictive Maintenance

Core Features:

- GenAI and AI based algorithms generate Machine Health Scores for each asset by analyzing control system and sensor data.

- Days to Next Maintenance is optimized based on real-time performance and health status of the machines.

- Data from sensors and insights creates a proactive approach that helps to schedule maintenance before a bottleneck occurs.

- Real-time monitoring of equipment conditions can detect faults that may lead to starved or blocked states.

- Critical alerts are promptly issued in response to significant events impacting the machine or its operating environment.

OEE Analysis

Overall Equipment Effectiveness (OEE) measures manufacturing efficiency by evaluating asset availability, performance, and quality, essential for maximizing productivity and reducing downtime

Core Features:

- Develop real-time insights powered by GenAI and machine learning to monitor OEE across all production lines and shifts.

- Instantly view assets that are not meeting performance expectations, enabling swift and informed decision-making.

- OEE monitoring allows for operations to assess the effects of changes made to equipment and process on a machine to machine and shift to shift basis.

- OEE provides real-time visibility into the production line to identify whether a machine is starved (waiting for input) or blocked (unable to pass on output).

- Once a bottleneck is identified, further analysis can determine its root cause (due to equipment failure, supply chain issues, or operational inefficiencies)

Shift Change Analytics

Attain seamless shift changes with superior GenAI-enabled insights for peak performance

Core Features:

- Utilize cycle time analysis to accurately forecast the number of jobs that will be completed during each shift.

- Access a whole-line perspective to detect and predict starved or blocked conditions and determine their root causes.

- Leverage cycle time analysis to pinpoint which assets or operators are underperforming during production shifts, enabling better management decisions.

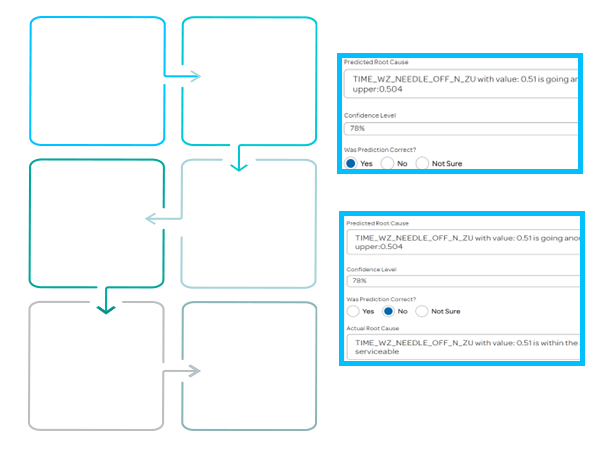

Root Cause Identification

Eliminate recurrent causes of downtime with closed-loop root cause identification and corrective action.

Core Features:

- Automatically generate and assign causality for immediate issue identification.

- SMEs and operators can further analyze causality to implement effective corrective actions.

- End-to-end intelligent workflows support fault detection, root cause analysis (RCA), and remediation activities.

- Gain better insights with comprehensive reporting on all OEE impactors, ensuring precise problem resolution.

Security & Monitoring

The benefits of AI cybersecurity and monitoring, all in one solution.

Core Features:

- Offers both AI-enabled security and dynamic monitoring.

- Only sends data when AI detects abnormal behavior, greatly reducing transmission costs

- Only transmits data that is critical to current cyber-security status.

- Low latency detection as MicroAI runs AI analytics directly on the endpoint

- Requires no historical or labeled data, train directly on the data available on the asset in real time.

Generative AI

Transforming data into insightful actions with real-time precision.

Core Features:

- Utilizes wealth of collected knowledge to provide recommendations on the most effective actions.

- The GenAI system is continuously updated and augmented by the Central Knowledge Base.

- Operates and provides insights and recommendations based on real time data for an optimized decision-making process.

- Dynamically render graphs and other visualizations based on queries to enhance recommendations.

- AI-based analytics and decision-making forms an end-to-end intelligent workflow system.

- Delivers precise and accurate outputs tailored to specific use cases.

- Enhanced by edge computing capabilities and a comprehensive knowledge base, ensuring robust domain expertise and observability.

GenAI Workflow and Analytics

Data Collection

Edge gateway is connected to assets to collect data.

1

GenAI Model Learns

Data flows into gateway in real time to build AI models.

2

GenAI Analytics

GenAI models flow to cloud and actionable analytics are produced.

3

Optimize Decisions

GenAI analytics trigger intelligent workflows that produce real-time insights and recommendations, enabling smart decisions.

4

Download Our White Paper

AI and 5G-Enabled Industrial Operations

Want to dive deeper into how MicroAI and AT&T are transforming industrial infrastructures? Download our comprehensive white paper “AI and 5G-Enabled Industrial Operations” to explore:

- The role of Generative AI in predictive maintenance and workflow automation

- How 5G and IoT improve connectivity and observability

- Real-world case studies on improving productivity and security in industrial operations

Download Now

MicroAI and AT&T are your trusted partners in building a fully connected,

AI-enabled industrial infrastructure.

Contact Us to learn how we can help revolutionize your industrial operations.