Machine Health Scores

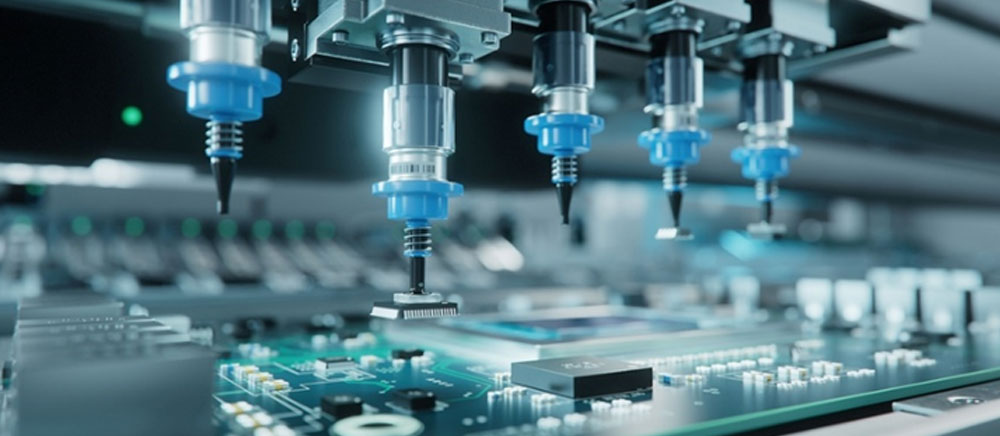

Today’s manufacturing and industrial operations are driven by machines that have been embedded with a wide variety of IoT devices (sensors, actuators, controllers, etc.). Those devices produce a flood of data. Utilizing that mass volume of data to produce highly targeted machine health scores is the next imperative within many industry 4.0 initiatives.

Machine Health Metrics

MicroAI utilizes the latest in endpoint AI technology combined with a powerful data aggregation and visualization engine to produce real-time machine heath scores that convert raw data into actionable insights.

Machine uptime

The amount of time the machine was operational during a given period.

Machine output

The amount of actual machine output compared to its maximum operating potential.

MTBF (mean time between failure):

A measurement of how long the machine operates between failure incidents. A vital indicator of machine reliability.

Failure root cause

Identification of the cause of failure and recommended corrective action(s).

MTR (mean time to repair)

A measurement of the amount of time elapsed between machine failure (machine down) and repair (machine back up).

First-pass yield

The percentage of machine-produced products that pass quality inspection with no rework required.

Machine Health Score Impacts

Deep machine observability

Ability to fast-track issue identification and corrective action and to identify recurring problems based on historical analytics.

Higher product yields

Rapid detection of machine performance issues that negatively impact the quality of the product(s) being produced.

Machine lifespan extension

Real-time asset health monitoring extends the lifespan of expensive assets.- Up to 50% reduction in machine downtime Double-digit increases in machine productivity Significant reductions in maintenance labor costs Up to 15% improvement in OEE scores Lower CoGS and improved competitive position

Explore relating Products & Solutions

Products

Machine Insight

Mission-critical machines within the manufacturing, telecom, automotive, and infrastructure segments are transformed from opaque entities into assets that are fully transparent. This transparency delivers deeper insights that produce predictive

Digital Factory

Digital Factory – Factory performance revolutionized. An AI-enabled plug-and-play solution that delivers predictive manufacturing, predictive maintenance, and improved OEE for manufacturers.