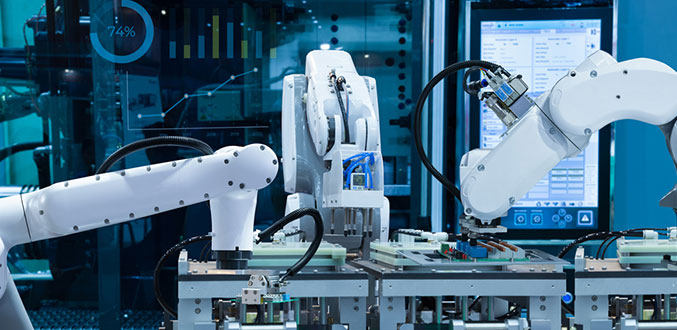

16 Dec Assembly Line Monitoring Using Advanced AI Technology

Assembly line productivity and uptime are critical metrics for any company in the manufacturing sector. In this article we will cover various aspects of monitoring and maintaining an assembly line using MicroAI™, a cutting-edge AI enablement solution that brings new capabilities to the realm of IIoT.

The Traditional Approach – Limitations

A traditional way to monitor an assembly line is to have a technician come in and perform a full diagnosis on the line’s performance. Depending on the type of equipment involved, this might be a single technician or a team of technicians. Historically, this approach has created several problems for the manufacturing operation. Those problems would include:

- Increased operational costs associated with the labor (technicians) required to perform the diagnosis

- Increased equipment downtimes due to failures that were not predicted

- Poor allocation of resources due to assignment of technicians to perform maintenance that may not be required

- Poor Overall Equipment Effectiveness (OEE) due to all of the above

The MicroAI™ Approach – More Effective Management of IIoT Assets

MicroAI™–an edge-based AI and machine learning algorithm—provides IIoT asset owners with deeper insights into the performance of the individual pieces of equipment contained within an assembly line. These real-time insights provide equipment operators and managers with the ability to maximize the performance, lifecycle, and security of critical assets.

Consider a simple use case of an assembly line containing six robotic arms arrayed along a conveyor belt. Each robotic arm will be performing its own individual task and will be equipped with various types of sensors (accelerometers, gyroscopes, vibration detectors, etc.).

Before we ingest data into MicroAI™ Atom, we will need to assess the amount of feature engineering that will be required to support our use case. It could be as simple as turning raw values into a whole number or a decimal number. Depending on the nature of the data, we can make the feature engineering as complex as necessary. Once the data has been cleaned and prepared for ingestion, we can begin the process of configuring and modeling the AI.

Now we are ready to start the AI engine and begin the monitoring process. At this point, we can also feature-engineer the MicroAI™ Atom output data to our requirements. We can use the MicroAI™ Atom output to generate events. These events can include sending the data to the cloud, sending email alerts to users via email or text, and more.

High frequency changes in data and the ability to detect abnormal behavior—in real time—requires data processing and anomaly detection on the edge. MicroAI™ Atom provides this capability. In addition, MicroAI™ Atom learns as it runs, so each setup will start to personalize according to its environment.

Using MicroAI™ Atom is this use case provides the assembly line operator with significant advantages, including:

- Ability to train an AI model to meet the user’s unique requirement

- Real-time insights into asset behavior

- Access to predictive analytics to determine the most efficient maintenance schedule

- Reduction in unexpected asset downtime

- Greater assembly line accuracy and output